Mechanical Fasteners- for EIFS and Plaster

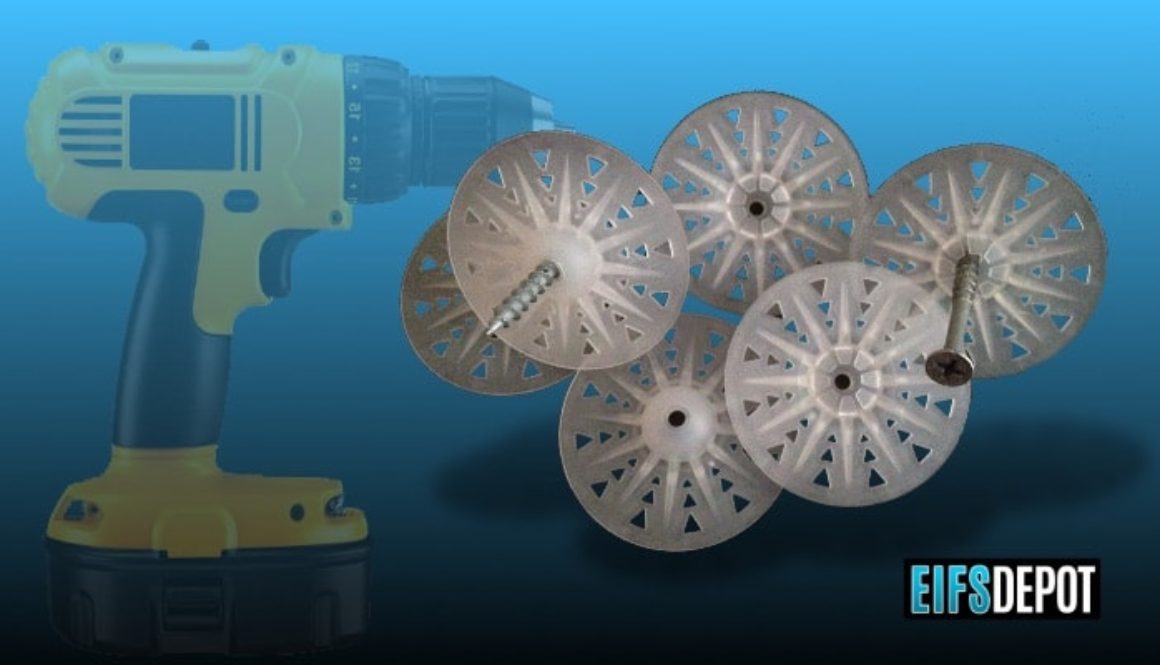

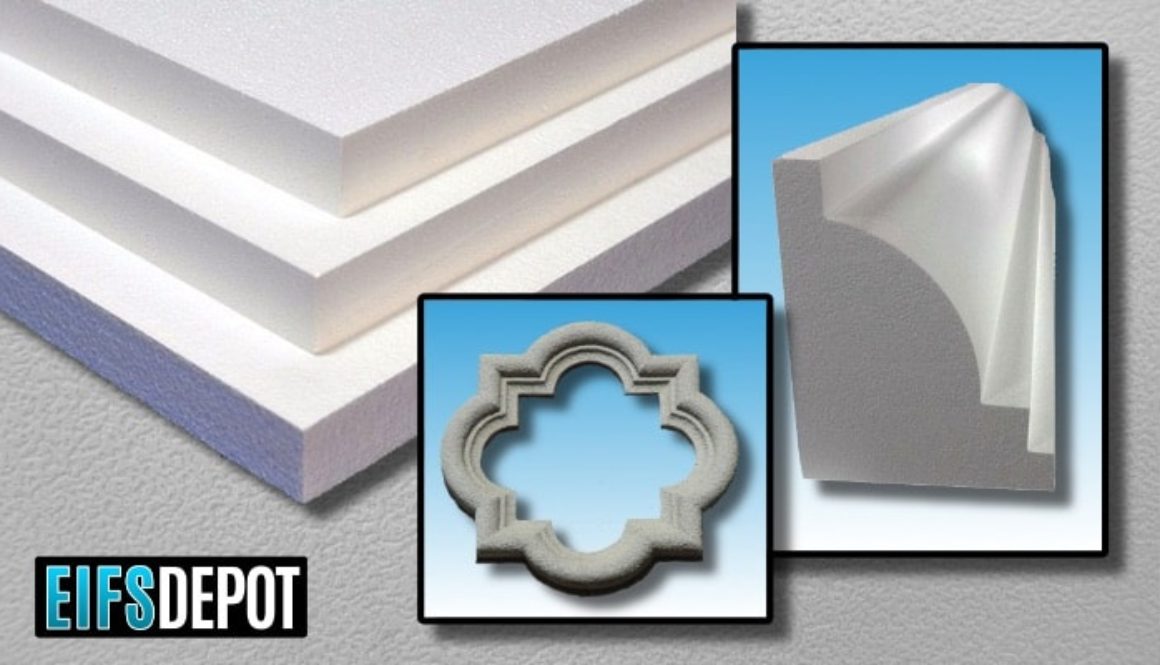

Mechanical Fasteners are primarily used when installing EIFS (exterior insulation and finish system). Mechanical fasteners are used to attach EPS (Expanded Polystyrene) foam board to plywood, osb, and light metals and other approved substrates. Extruded polystyrene (xps) and polyisocyanurate foams can also be used in the place of EPS foam board. Mechanical fasteners are designed so the screw will pass through EPS foam and the washer will stop the head of the screw from passing completely through the foam board, countersinking the plastic stop washer and leaving the surface flush. This is very important because installers may need to rasp any uneven Foam surfaces and then apply a layer of Basecoat Adhesive on top of the eps foam board with a trowel and embed Fiberglass Mesh into the Basecoat.

Mechanical Fasteners are comprised of a pre-assembled galvanized steel screw that is coupled with a high density, impact resistant two inch plastic stop washer. The large diameter of the washer provides strong resistance to positive and negative wind loads. The recessed channel with the plastic closures over the top prevent moisture from passing through, bleeding of basecoat, and prevents thermal bridging, as well as covering the screw head so that there is a flush surface. The recessed area of the fastener makes it so very little Basecoat adhesive to is needed to fill the indention in the EPS board.

When installing an EIFS system with mechanical fasteners, it is important that one use an air and moisture barrier such as stucco wrap. In a system attached with adhesive, a roll on barrier is used which creates a membrane to protect the substrate from air and moisture vapor. A roll on barrier should not be used on a mechanically attached system because the screws penetrate the membrane therefore defeating the purpose of a water and air tight membrane. In addition to using a moisture barrier, an installer must be sure that areas around windows, doors, soffits, and the roof line are properly flashed.

One significant advantage of using mechanical fasteners is that you do not have to wait a day for adhesive to dry as with a system that is attached with adhesive. An installer can attach the EPS foam, basecoat and install fiberglass mesh on the same day. Since the washer and screw are pre-assembled, a mechanically attached system can be installed fairly quickly. It is recommended by most manufacturers to use one fastener per square foot for proper strength.

It is important to follow architect specifications, local building codes, and manufacturer’s recommendations when installing an EIFS system. Different regions may require either a system attached with adhesive, mechanically attached, or a combination of the two due to humidity, average temperature, and/or wind speeds. Some regions may need to be attached with both adhesive and fasteners. When purchasing pre-assembled mechanical fasteners, the key is to buy a fastener with a screw length that is slightly longer than the thickness of your foam board. See chart below.